-

Calcium Sulphate Anti-Static Raised Floor With PVC Covering

The high-density calcium sulphate anti-static raised floor with PVC covering is made of raw materials that are processed and solidified into calcium sulphate crystals, and non-toxic and unbleached plant fibers are used as reinforcement materials through a pulse pressing process.

-

All Steel Anti-Static Raised Floor With HPL Covering

All steel anti-static raised floor with HPL covering adopts ST14 tensile plate for the bottom, and SPCC flinty steel sheet is selected for the surface. After stretching, spot welding is conducted to form an all steel shell structure.

-

All Steel Anti-Static Raised Floor With PVC Covering

The all-steel anti-static raised floor with PVC covering adopts a steel base layer, and the surface is pasted with a homogeneous and transparent PVC covering. Steel pedestals of different elevations and pipe diameters can be customized to meet different raised heights and load-bearing needs. The height of the pedestal can be fine-tuned to solve the problem of local subtle height differences of ground.

-

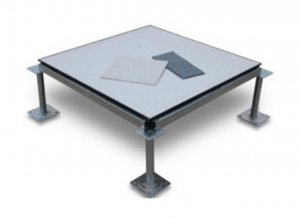

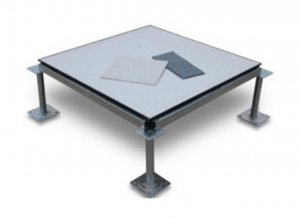

All Steel Anti-Static Raised Floor With Ceramic Covering

All steel anti-static raised floor with ceramic covering adopts high-quality alloy cold-rolled steel plate, which is formed by spot welding after stretching. The surface is phosphated and then sprayed, the inner cavity is filled with foam filler, and the upper surface is pasted with high wear-resistant and anti-static vitrified embryo ceramics.

-

All steel encapsulated network raised floor

All steel encapsulated network raised floor, also known as OA network raised floor, is formed by spot welding after stretching of high-quality cold-rolled steel sheet, the inner part is filled with foamed cement, and the surface is dealt with plastic spraying after phosphating.