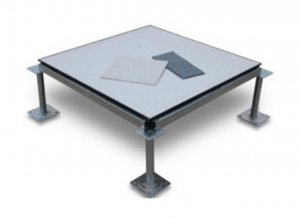

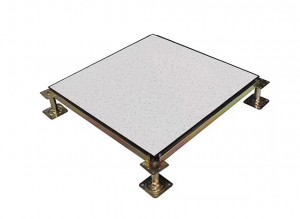

All steel encapsulated network raised floor

All steel encapsulated network raised floor

All steel encapsulated network raised floor, also known as OA network raised floor, is formed by spot welding after stretching of high-quality cold-rolled steel sheet, the inner part is filled with foamed cement, and the surface is dealt with plastic spraying after phosphating.

Parameters

| OA500 network raised floor | ||||

| Specification(mm) | Concentrated Load | Uniform Load | Deflection(mm) | |

| 500*500*28 | ≥1960N | ≥200KG | ≥9720N/㎡ | ≤2.0mm |

| 500*500*28 | ≥2950N | ≥301KG | ≥12500N/㎡ | ≤2.0mm |

| 500*500*28 | ≥3560N | ≥363KG | ≥16000N/㎡ | ≤2.0mm |

| 500*500*28 | ≥4450N | ≥454KG | ≥23000N/㎡ | ≤2.0mm |

| OA600 network raised floor | ||||

| Specification(mm) | Concentrated Load | Uniform Load | Deflection(mm) | |

| 600*600*33 | ≥1960N | ≥200KG | ≥9720N/㎡ | ≤2.0mm |

| 600*600*33 | ≥2950N | ≥301KG | ≥12500N/㎡ | ≤2.0mm |

| 600*600*33 | ≥3560N | ≥363KG | ≥16100N/㎡ | ≤2.0mm |

| 600*600*33 | ≥4450N | ≥454KG | ≥23000N/㎡ | ≤2.0mm |

Key Performance Characteristics

● Lightweight cement infill makes the steel raised floor panel solid and quiet

● Metalic Surface Pretreatment and Epoxy Paint Finish make panel for life time protection

● Class A flame spread rating

● Completely non-combustible

● All-steel pedestals provide excellent impact load performance

● Panels are convenient to interchange

● The whole system are easy to install

● Cost saving and environmentally friendly

Application

● Office spaces

● Classroom

● Training facilities

● Libraries

● Meeting rooms

● The places where demand wiring and cabling, and the old building floor renovation

Advantage

1. High load-bearing capacity: steel structure, strong impact resistance, and the bearing capacity can be evenly dispersed through the pedestal.

2. Simple installation: the specific plane layout of office electrical equipment and furniture location does not need to be considered in the decoration design. Only the height difference between the ground without network raised floor and the ground with network raised floor is considered. At the same time, the height is low and adjustable, which saves more space than the traditional raised floor.

3. Easy to use: the network floor is easy to install. There is a real-time relay system to facilitate the extraction of lines. It can output from any point in the area without cutting off the network raised floor. It is compatible with various types of socket boxes. Users can adjust the socket position by themselves, while the traditional raised floor is not easy to replace by themselves.

4. High security: weight reduction of network raised floor: about 2 / 3 of the weight of traditional mobile floor, which reduces the load of floor and is safer than traditional floor.

5. Convenient maintenance: the network floor has good interchangeability, flexible assembly, convenient maintenance and high reuse rate.

Attention

Trunking can be added around the floor according to the usage requirements, which makes the wiring more flexible, and can separate the strong and weak current. It is convenient for maintenance, saves the building space and reflects the functionality of the raised floor. The floor is constituted by all-steel and is compression molding, so that it has excellent fire-proof and corrosion resistance. There are corner keyholes around to ensure the overall stability of the floor installation, and it can be laid with square carpet, PVC veneer or solid wood floor. It is mostly used in 5A office buildings and intelligent office places.