Wholesale Price Anti Static Hpl - All Steel Anti-Static Raised Floor With HPL Covering – Senmai

Wholesale Price Anti Static Hpl - All Steel Anti-Static Raised Floor With HPL Covering – Senmai Detail:

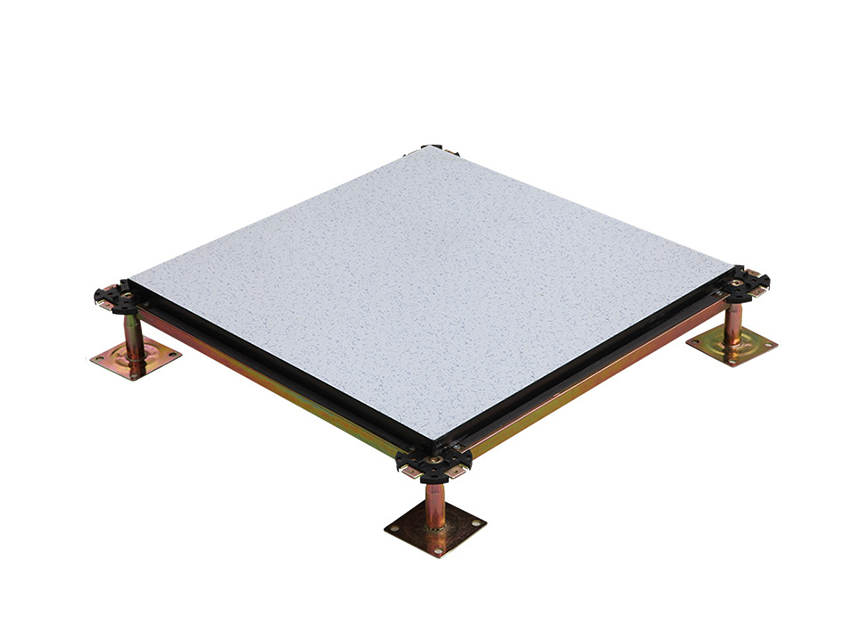

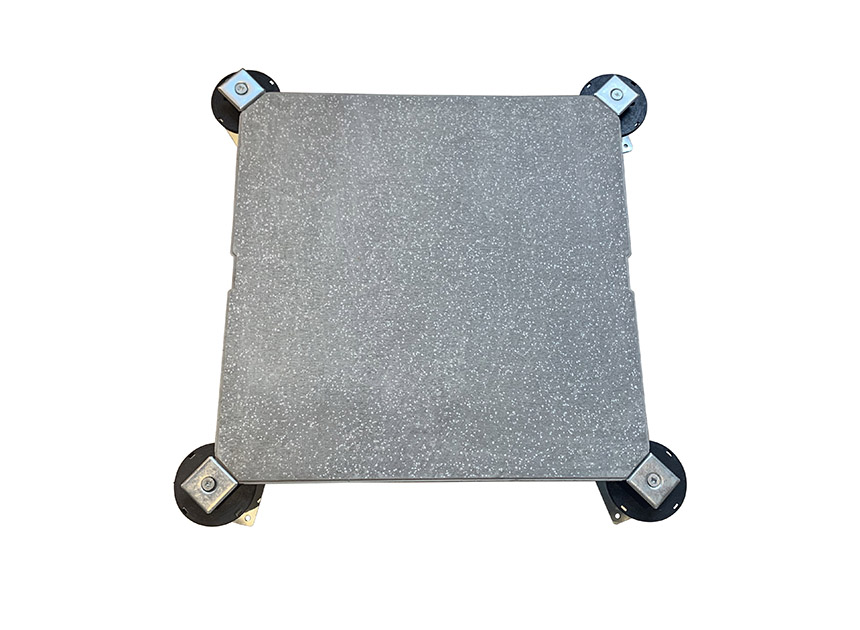

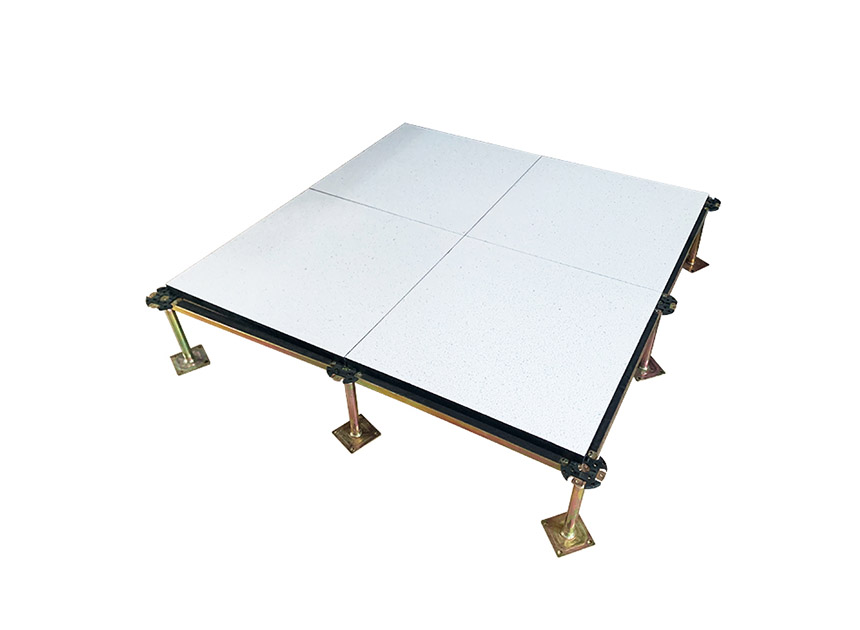

All Steel Anti-Static Raised Floor With HPL Covering

All steel anti-static raised floor with HPL covering adopts ST14 tensile plate for the bottom, and SPCC flinty steel sheet is selected for the surface. After stretching, spot welding is conducted to form an all steel shell structure.

The surface is dealt with plastic spraying after phosphating, and the interior is filled with foamed cement, which has good sound-absorbing, heat insulation and fire resistance.

Parameters

|

All Steel Anti-Static Raised Floor With HPL Covering |

||||

|

Specification(mm) |

Concentrated Load |

Uniform Load |

Deflection(mm) |

|

|

600*600*35 |

≥1960N |

≥200KG |

≥9720N/㎡ |

≤2.0mm |

|

600*600*35 |

≥2950N |

≥301KG |

≥12500N/㎡ |

≤2.0mm |

|

600*600*35 |

≥3550N |

≥363KG |

≥16100N/㎡ |

≤2.0mm |

|

600*600*35 |

≥4450N |

≥453KG |

≥23000N/㎡ |

≤2.0mm |

|

System Resistance |

Conductivity type R<10^6 Anti-Static1*10^6~1*10^10 |

|||

Key Performance Characteristics

● Strong bearing capacity

● Wear-resistant

● High-temperature resistant

● Cleaning resistant

● Anti-permeable

● Waterproof, fireproof, dust-proof

● Shock-proof

● Flat and not easy to scratch

● Very easy to maintain

● High mechanical strength

Application

● Constant temperature rooms

● School computer rooms

● Meeting rooms

● Radio control rooms

● Communications rooms

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for Wholesale Price Anti Static Hpl - All Steel Anti-Static Raised Floor With HPL Covering – Senmai , The product will supply to all over the world, such as: Johor, Kazakhstan, Cape Town, Although continuous opportunity, we have now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.