Factory directly supply Raised Vinyl Flooring - All Steel Anti-Static Raised Floor With PVC Covering – Senmai

Factory directly supply Raised Vinyl Flooring - All Steel Anti-Static Raised Floor With PVC Covering – Senmai Detail:

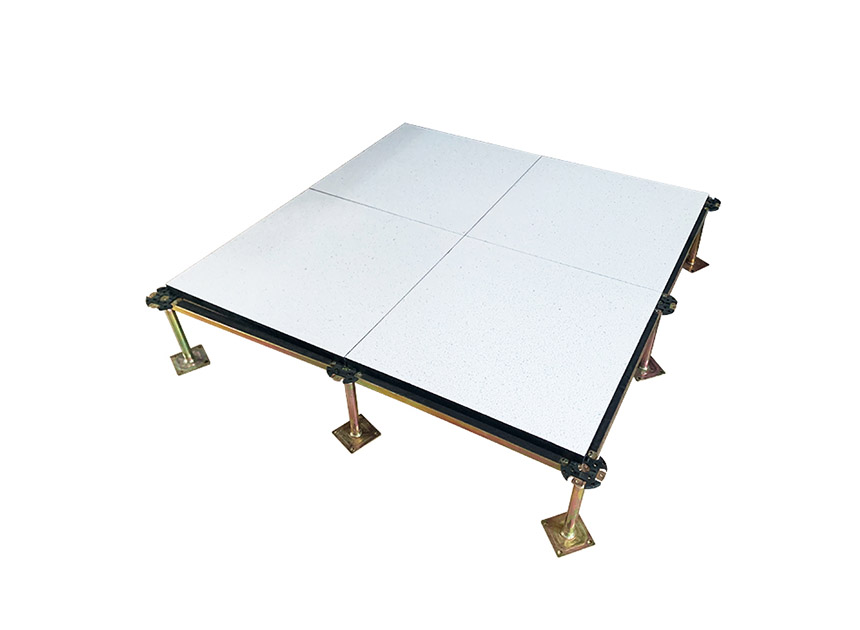

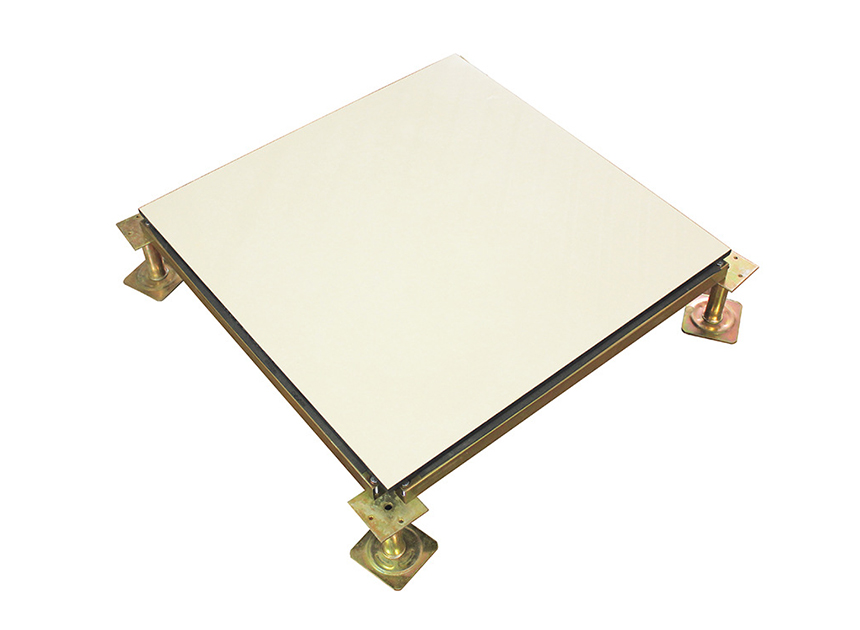

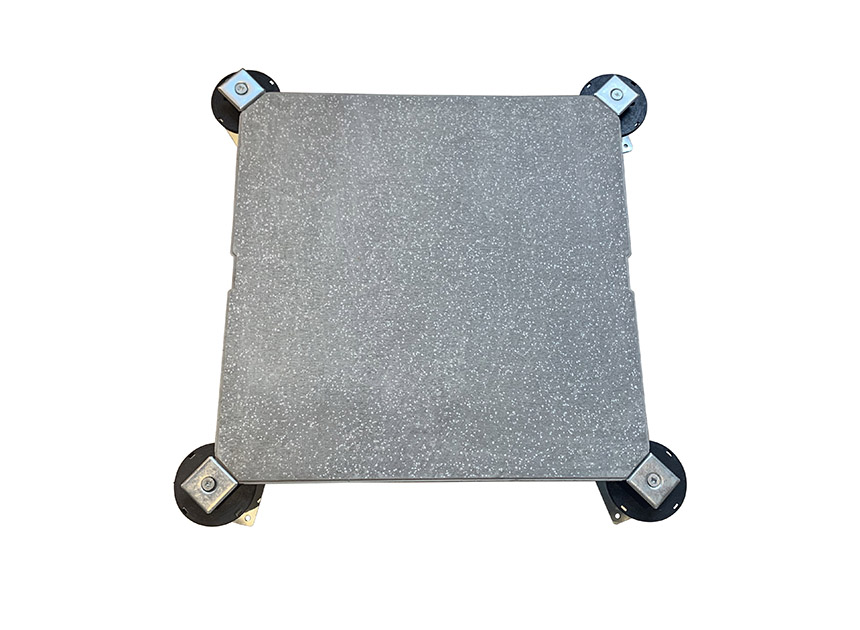

All Steel Anti-Static Raised Floor With PVC Covering

PVC anti-static covering is mainly made of polyvinyl chloride resin through special processing technology. The electrostatic conductive network is formed between the PVC particle interface, which has excellent electrical conductivity. There are multiple patterns on the surface of PVC, which resembles marble pattern. It has certain wear resistance, slightly lower than HPL covering, but it has powerful anti-static function, long-lasting anti-static feature, aging resistance and low dust generation.

Parameters

|

All Steel Anti-Static Raised Floor With PVC Covering |

||||

|

Specification(mm) |

Concentrated Load |

Uniform Load |

Deflection(mm) |

|

|

600*600*35 |

≥1960N |

≥200KG |

≥9720N/㎡ |

≤2.0mm |

|

600*600*35 |

≥2950N |

≥301KG |

≥12500N/㎡ |

≤2.0mm |

|

600*600*35 |

≥3550N |

≥363KG |

≥16100N/㎡ | ≤2.0mm |

|

600*600*35 |

≥4450N |

≥453KG |

≥23000N/㎡ | ≤2.0mm |

|

System Resistance |

Conductivity type R<10^6 Anti-Static1*10^6~1*10^10 |

|||

Key Performance Characteristics

● Excellent electrical conductivity

● Good fireproof performance

● Good durability

● Good load-bearing

● Outstanding decorative effect

● Excellent ductility

● Moisture proof

● Not easily deformed

● Soundproofing

● Flexible assembly

● No foaming and degumming

Application

● Electronic workshops

● Clean workshops

● Microelectronics workshops

● Radio control rooms

● Communications rooms

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for Factory directly supply Raised Vinyl Flooring - All Steel Anti-Static Raised Floor With PVC Covering – Senmai , The product will supply to all over the world, such as: Malaysia, Vietnam, Finland, The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.